Rotational Molding – The Ideal Process for Manufacturing

Whatever industry you work in, there is a solid probability that micro segments have an impact in the work you do. From oil and fuel tanks to taxis for tractors and JCBs, from channels and pipes to clinical hardware, micro parts are all over the place. Organizations are consistently keeping watch for increasingly dependable and cost-proficient methods of mass-creating the parts they need. Rotational embellishment is an especially savvy process for assembling empty micro items. Since this procedure is so flexible and almost no waste is created, costs are low contrasted with other micro assembling forms for example, blow embellishment or infusion shaping.

How the rotational embellishment process functions?

In all honesty, the procedure which is utilized to make such a flexible scope of micro items was initially produced for making chocolate Easter eggs. In spite of the fact that the innovation is unquestionably increasingly advanced nowadays, the essential rotational embellishment process continues as before. In rotational embellishment, polymer powder is gradually tumbled in a warmed, encased form. The powder liquefies, shaping a covering over the inside surface of the form. The form is cooled, permitting the polymer covering to get strong. The form is then opened and a precisely molded micro part is separated. Rotational embellishment is a profoundly flexible strategy for making an exact, stress and crease free micro item at nearly minimal effort. The procedure can create complex shapes with controlled divider thickness in an assortment of materials. It is especially appropriate for assembling empty or incompletely empty pieces.

In all honesty, the procedure which is utilized to make such a flexible scope of micro items was initially produced for making chocolate Easter eggs. In spite of the fact that the innovation is unquestionably increasingly advanced nowadays, the essential rotational embellishment process continues as before. In rotational embellishment, polymer powder is gradually tumbled in a warmed, encased form. The powder liquefies, shaping a covering over the inside surface of the form. The form is cooled, permitting the polymer covering to get strong. The form is then opened and a precisely molded micro part is separated. Rotational embellishment is a profoundly flexible strategy for making an exact, stress and crease free micro item at nearly minimal effort. The procedure can create complex shapes with controlled divider thickness in an assortment of materials. It is especially appropriate for assembling empty or incompletely empty pieces.

By choosing from a scope of various materials, articles with physical properties as shifted as adaptable gearstick gaiters or inflexible business vehicle taxi parts can be made. Metal embeds for example, strings and shrubberies can be shaped in and formed pits loaded up with froth. On the other hand strings might be a piece of the formed shape itself in micro molding. Moldings might be CNC machined, penetrated, sawn, directed, tapped or welded. The presence of the item can be improved by applying a surface or paint. The look and feel of different materials for example, metal and calfskin can likewise be recreated. In the event that greater inflexibility or protection is a piece of the structure, an inward froth layer can either be formed necessarily or infused into empty segments subsequent to embellishment.

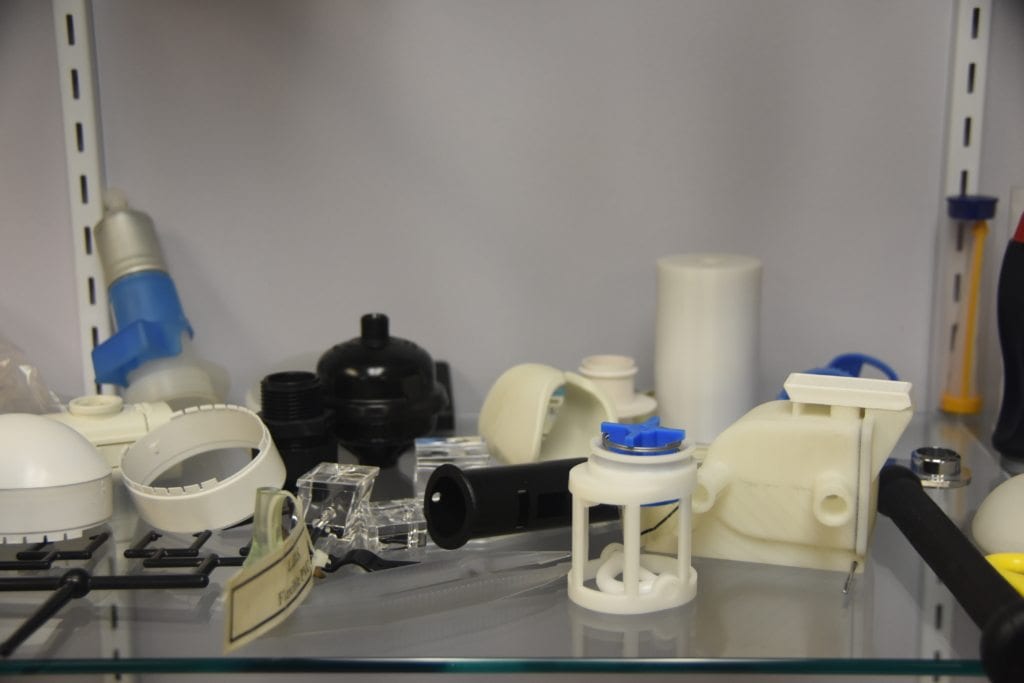

Rotational embellishment can create a colossal assortment of micro items

The utilizations for roto moulding are broad, extending a long ways past the fundamental encased box or tank for which the procedure is most popular medical micro molding. Rotational trim can create segments for hardware, furniture and fittings for airplane, even items for the home or nursery. By picking the right polymer, techno-structure can deliver articles with different physical properties: along these lines the outcome can run from amazingly adaptable inflatable even to unbending and effect safe for example, a defensive topping.