Real Time Vibration Monitoring An Important Tool In Preventive Maintenance

Condition monitoring entails examining a parameter of illness of machines or equipment as a predictive maintenance measure. Machines with flaws evidently have more risk of failure compared to those free of flaws. Condition monitoring ensures on-time scheduling of maintenance and similar measures to prevent failure of machinery.Vibrations in some cases like the movement of a tuning fork and the drone of a loudspeaker are desirable because they play a very important role in the functioning of the equipment. However, in most other instances, vibration harms the gear by wasting electricity and generating unwanted sound. Such vibration is usually brought on by imbalance in rotating parts and irregular friction.

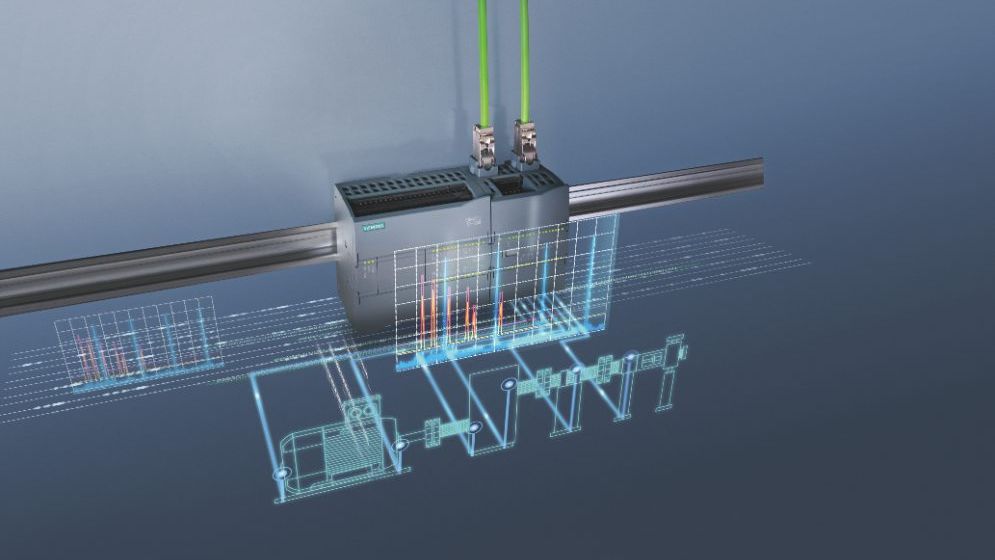

Best real time vibration monitoring is a commonly used instrument to execute exhaustive condition monitoring exercises. The dawn of Fast Fourier Transform mathematical method made accessible mobile spectrum analysis equipment to measure machinery vibration. Mechanical conditions of a system can now be examined even while it is in operation. Traditionally, information from vibration sensors is recorded and examined through mobile vibration testing systems.Such systems allow engineers to survey Present vibrations and Predict future ones in addition to their effect, thus helping in the development of mitigation measures. For large industrial set-ups and expensive equipment, this functions as a cost-effective state monitoring step.Condition monitoring systems with a strong emphasis on vibration testing are becoming a standard in identification and prevention of failures, particularly for rotating equipment. Successful vibration analysis for such equipment involves installation of vibration testers and comparison of data with baseline values to estimate the flaws, if any.

Gear such as cooling fans, which find application in Several businesses to remove heat from additional material is more likely to wear-and-tear because of vibrations and so requires regular condition monitoring. The constant use of its fan, blade, equipment, motor and posture cause vibrations and irregular observation of the equipment can be catastrophic. Vibration testing equipment can quantify the anticipated gear mesh frequency, blade passing, bearing defect frequencies, fan balance and motor alignment.The ever-growing maintenance costs induce businesses to sustain the health of their equipment’s. The introduction of new-age vibration analysis Equipment and mobile vibration testers make it possible for engineers to monitor vital Parameters of the equipment and troubleshoot before breakdown. Implementation Of strong vibration testing equipment is crucial to derive in a quality vibration analysis and condition monitoring exercise.